Rigid PU Composite Insulation Board Series – ZDW

Rigid PU Composite Insulation Board Series – ZDW Detail:

Product Description

The rigid foam polyurethane composite insulation board is an insulation board with rigid foam polyurethane insulation material as the core material and a cement-based protective layer on both sides. It adopts continuous production equipment-secondary molding, which not only meets the high standards of building energy-saving insulation, but also enhances The stability of the system; the board has dual interfaces when it leaves the factory, which can effectively avoid the fire caused by cigarette butts and electric welding during the transportation, construction site stacking and wall construction; rigid foam polyurethane is a thermosetting material and will not be exposed to fire. Melting, no burning droplets, no flame propagation after forming the system, greatly improving the fire resistance during use. The double-sided cement-based surface layer can enhance the bonding strength of the insulation board, the adhesive and the plastering mortar, thereby ensuring the integrity and stability of the system.

Technical Indicators

| item | unit | Technical Data |

| Density ≥ | kg/m3 | ≥35kg/m3 |

| thermal conductivity ≤ | W(m.K) | 0.021W(m.K) |

| Water absorption rate ≤ | % | 3% |

| Flammability rating | 级 | B1 B2 |

| compressive strength≥ | Kpa | ≥150KPa |

Product specifications

| (mm)Length | (mm)Width | (mm)Thickness |

| 1200 | 600 | 10-100 |

Product category

01| Thermal insulation

Rigid polyurethane foam has a highly cross-linked structure, basically closed-cell (opening rate 5%), and extremely low thermal conductivity, only 0.021W/(m.K).

02| Economy

It has a long use time and good thermal insulation performance. Its thickness is 2/3 thinner than thermal insulation slurry and 1/3 thinner than polystyrene board. The comprehensive cost performance per unit square area is excellent.

03|stability

Polyurethane rigid foam mainly adopts special halogen-free flame-retardant polyether polyol, and adds a phosphorus-based flame retardant with a synergistic effect to achieve a halogen-free flame-retardant structure in the foam molecules without increasing the amount of isocyanate. The flame-retardant performance has reached the B1 standard; the polyurethane external wall insulation system has passed multi-project and multi-system demonstration, and there will be no phenomenon of insulation material falling off after engineering application.

04|Environmental protection

Adopting fluorine-free foaming technology and aldehyde-free products, it belongs to green building materials.

05|Durability

It has good chemical resistance and can be used for a long time at a temperature of -180°C ~150C. It has excellent weather resistance and freeze-thaw resistance and can be used for up to 50 years.

06|Construction

The construction process is simple, safe and reliable, and different construction processes can be selected for different purposes.

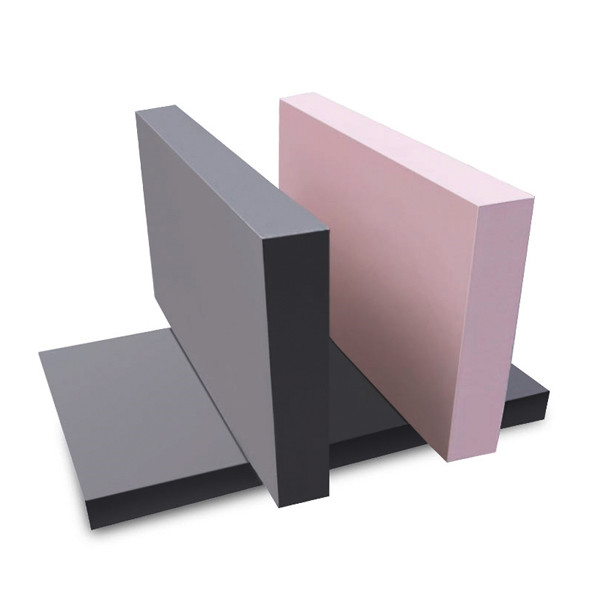

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency profits team values customers' requirements and organization communication for Rigid PU Composite Insulation Board Series – ZDW , The product will supply to all over the world, such as: Bulgaria, Tunisia, Uzbekistan, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!