Products

-

PU foam Insulation Board Series

Description The rigid foam polyurethane composite insulation board is an insulation board with rigid foam polyurethane insulation material as the core material and a cement-based protective layer on both sides. It adopts continuous production equipment-secondary molding, which not only meets the high standards of building energy-saving insulation, but also enhances The stability of the system; the board has dual interfaces when it leaves the factory, which can effectively avoid the ... -

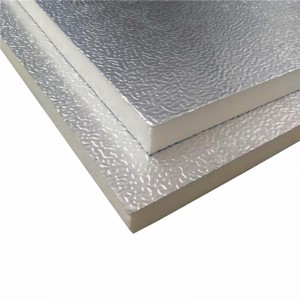

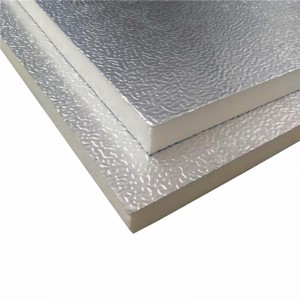

Double-sided aluminum foil composite phenolic wall insulation board

The double-sided aluminum foil composite phenolic foam insulation board is composited through a continuous production line at one time. It adopts the sandwich structure principle. The middle layer is closed-cell phenolic foam, and the upper and lower layers are covered with a layer of embossed aluminumfoil on the surface.

-

Rigid PU Composite Insulation Board Series

The rigid foam polyurethane composite insulation board is an insulation board with rigid foam polyurethane insulation material as the core material and a cement-based protective layer on both sides.

-

Polyurethane (PU) Foam Pre-Insulated HVAC Ductwork Panel

PU Foam insulated Duct Panel with Aluminum Foil is used for central air conditioning duct system. It is energy saving and environment frendly. It had become more and more popular all over the world.

-

Modified phenolic fireproof insulation board

Modified phenolic fireproof insulation board is a new generation of thermal insulation, fireproof and sound insulation material. The material has the advantages of good flame resistance, low smoke emission, stable high temperature performance, heat insulation, sound insulation, and strong durability. The material strictly controls the water content, phenol content, aldehyde content, fluidity, curing speed and other technical indicators of the phenolic resin to achieve outstanding improvements in flexibility, adhesion, heat resistance, ablation resistance, etc. New varieties. These characteristics of phenolic foam are an effective way to improve the fire safety of walls. Therefore, phenolic foam is currently the most suitable insulation material to solve the fire safety of external wall insulation systems.

-

Single Side GI Composite Phenolic Foam Insulation Duct Panel

The embossed Galvanized steel phenolic air duct sheet is a new generation evolution product of traditional iron sheet air duct. The outer layer of the air duct board is made of galvanized embossed steel plate, the inner layer is coated with anticorrosive aluminum foil, and the middle is composited with phenolic foam. In addition to the advantages of traditional iron sheet air ducts of good rigidity and high strength, it also has the properties of flame retardant heat preservation, sound absorption and noise reduction. Moreover, after the pipe is formed, no secondary heat preservation is required, which overcomes the weakness of the traditional iron sheet air duct that the outer heat preservation layer is easily damaged, has a longer service life, and is beautiful and generous.

-

Double Sides Aluminum Foil Composite PhenolicFoam Insulation Duct Panel

The double-sided aluminum foil composite phenolic foam insulation air duct board is composited through a continuous production line at one time. It adopts the sandwich structure principle. The middle layer is closed-cell phenolic foam, and the upper and lower cover layers are embossed aluminum foil on the surface. The aluminum foil pattern is treated with anti-corrosion coating, and the appearance is corrosion-resistant. At the same time, it has the advantages of environmental protection, light weight, convenient installation, time-saving and labor-saving, and high-efficiency heat preservation function.

-

Double Sides color steel Composite PhenolicFoam Insulation Duct Panel

Phenolic Foam Insulation Panel both sides with Color Steel Sheet Panel Structure: Phenolic Foam as core material, both sides composited Color Steel Sheet Double-sided color steel composite phenolic foam insulation air duct sheet is an upgraded product of single-sided color steel composite phenolic foam insulation air duct sheet. It is a special ventilation product produced for users of subway, high-speed railway and high-clean environment projects. It is a traditional iron sheet wind. The upgraded product of the pipe solves the shortcomings of the traditional air pipe products in the application of easy damage, corrosion, and difficult to clean. It is a high-end product.

-

Single Side GI Composite Phenolic Foam Insulation Duct Panel

The embossed Galvanized steel phenolic air duct sheet is a new generation evolution product of traditional iron sheet air duct. The outer layer of the air duct board is made of galvanized embossed steel plate, the inner layer is coated with anticorrosive aluminum foil, and the middle is composited with phenolic foam. In addition to the advantages of traditional iron sheet air ducts of good rigidity and high strength, it also has the properties of flame retardant heat preservation, sound absorption and noise reduction. Moreover, after the pipe is formed, no secondary heat preservation is required, which overcomes the weakness of the traditional iron sheet air duct that the outer heat preservation layer is easily damaged, has a longer service life, and is beautiful and generous.

-

Phenolic Resin for Exterior Insulation Board

The resin uses melamine and resorcinol double modification technology to control the high ortho structure and methylol concentration of phenolic resin, and develops a phenolic resin with a foaming process similar to polyurethane foaming. The resin is at a certain temperature. Foaming also has obvious emulsification time, foam rise time, gel time, and curing time. It has achieved a revolutionary breakthrough in the foam production process, and can be used in the production line of continuous phenolic foam boards. The produced foam has the advantages of good dimensional stability, fine foam and low thermal conductivity.

-

Phenolic Resin for Composite Duct Board

Our R&D team has developed a special phenolic resin by using modification technology to control the high ortho structure and methylol concentration of the phenolic resin. The resin foams at a certain temperature and can be used for continuous production of metal surface composite phenolic foam panels. superior. The produced foam has the advantages of good dimensional stability, good adhesion, fine foam and low thermal conductivity.

-

Phenolic Resin for Flower Mud

The resin is modified with a small amount of urea, and the phenolic foam produced with this resin has an open cell rate of 100%. The weight water absorption rate is as high as 20 times, and the flower mud has a good fresh-keeping effect.