Phenolic insulation board is made of phenolic foam. Phenolic foam is a new type of non-combustible, fireproof and low-smoke insulation material. It is a closed-cell rigid foam made of phenolic resin with foaming agent, curing agent and other additives. Its most prominent feature is non-combustibility, low smoke, and resistance to high temperature dismutation. It overcomes the shortcomings of the original foam plastic insulation material that is flammable, smokey, and deforms when exposed to heat, and retains the characteristics of the original foam plastic insulation material, such as light weight and convenient construction.

Phenolic insulation board has the highest fire rating among many organic insulation materials

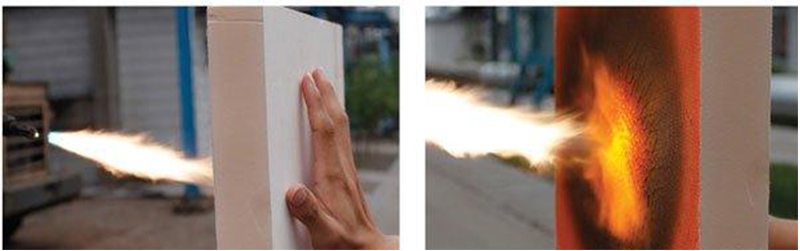

1) Excellent fire performance

Phenolic foam insulation materials (boards) are thermosetting plastics, and they have fixed fire protection performance without adding any flame retardants. It has a body-shaped polymer and a stable aromatic structure. According to the GB8624 standard fire rating, the phenolic foam itself can easily reach the B1 fire rating, which is close to the A level (tested in accordance with the GB8624-2012 standard), and the fire performance level is located in the B1-A level. Between the two (according to relevant information, Japan has designated phenolic insulation board as a "quasi-non-combustible" product).

The insulation layer is made of phenolic foam and combined with other materials for building insulation. It can basically reach the national fire protection standard A, which fundamentally eliminates the possibility of external insulation fire. The temperature range is -250℃~+150℃.

2) Outstanding effect of heat preservation and energy saving

Phenolic insulation board has good thermal insulation performance, and its thermal conductivity is about 0.023W/(m·k), which is far lower than the inorganic and organic exterior wall insulation products commonly used in the market at present, and can achieve higher energy-saving effects.

3) Wide range of uses

It can not only be used in traditional external wall thermal insulation system, but also can be combined with the decorative layer to make thermal insulation and decoration integrated board. It can also be used to construct the traditional EPS/XPS/PU external wall thermal insulation system fire isolation belt, which is used as the fire protection in the curtain wall. Thermal insulation materials, thermal insulation materials in fire doors, and fire thermal insulation materials for low or high temperature occasions. It is more suitable for workshops where the high temperature exceeds 50 degrees.

Post time: Aug-09-2021