High-performance phenolic foam energy-saving material

Phenolic foam board is made of phenolic foam. Phenolic foam material is a polymer organic product, which is foamed by thermosetting phenolic resin. Phenolic foam board is a very ideal fireproof, heat insulation, energy saving, beautiful and environmentally friendly green thermal insulation material

Phenolic insulation board has the highest fire rating among many organic insulation materials

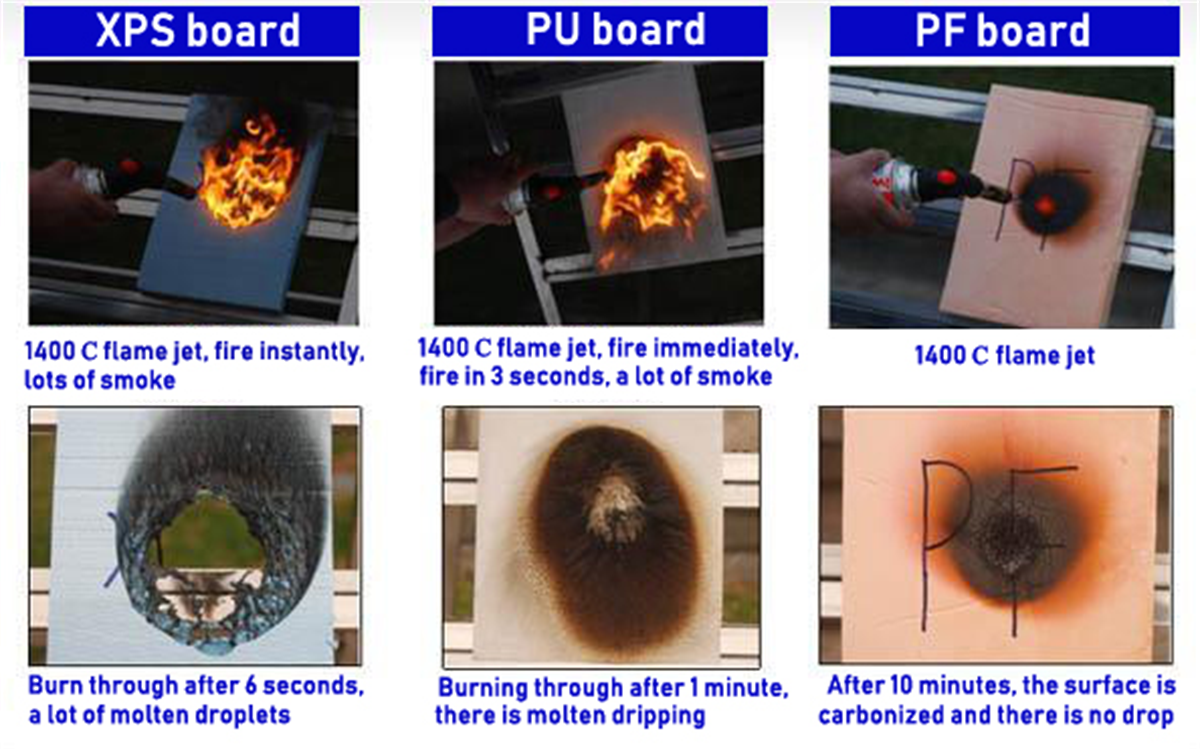

Phenolic foam insulation material (board) is a thermosetting plastic, and it has fixed fire resistance without adding any flame retardant. It has bulk polymer and stable aromatic structure. According to the fire rating of GB8624 standard, phenolic foam itself can easily reach the fire rating of B1, which is close to A (tested according to GB8624-2012), and its fire performance is at B1-A. Between the two (according to relevant information, Japan has designated phenolic insulation boards as "quasi non-combustible" products).

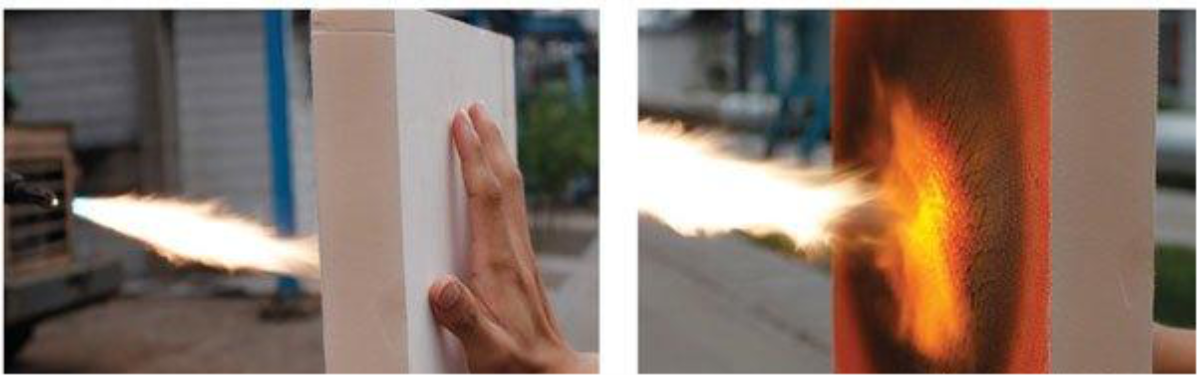

The outstanding feature of phenolic foam insulation material is that under the direct contact of ultra-high temperature open fire, a carbonized skeleton and gaseous substances such as CO and CO2 are formed. Spreading, only carbonization occurs on the surface of phenolic foam without molten dripping, and the phenolic foam board exhibits excellent flame penetration resistance.

Product Features

Thermal insulation

The phenolic foam has a uniform and fine closed-cell structure, and the thermal conductivity is lower than 0.022W/(m•K). Good thermal stability, wide operating temperature range (-180 ~ +180 ℃).

Fire retardant

Phenolic foam board is fire-resistant, flame-retardant, non-combustible in case of open flame, smoke-free, non-toxic, and non-dropping.

Corrosion and aging resistance

The dimensional change rate is less than 1%, and the stability is good. The chemical composition is stable, and it is resistant to corrosion by organic solutions, strong acids and weak bases, and has good aging resistance.

Green insulation

The phenolic foam board does not use freon as a foaming agent in the production process, which is in line with international environmental protection standards, and its molecular structure contains hydrogen, oxygen, and carbon elements. Harmless, in line with the national green environmental protection requirements.

Application

1) External thermal insulation of building exterior walls (thin plastering system, integration of thermal insulation and decoration, curtain wall system)

2) Insulation of central air-conditioning composite air duct (steel surface type phenolic composite air duct, double-sided aluminum foil phenolic composite air duct)

3) Color steel sandwich panel field (mobile board room, purification project, clean workshop, cold storage, cabinet room, etc.)

4) Roof insulation (residential roof, factory roof, roof insulation brick)

5) Insulation of cryogenic pipelines (LNG pipelines, LNG pipelines, hot and cold water pipelines)

6) Tunnel insulation

7) Various other fields that require thermal insulation

Post time: Mar-03-2022